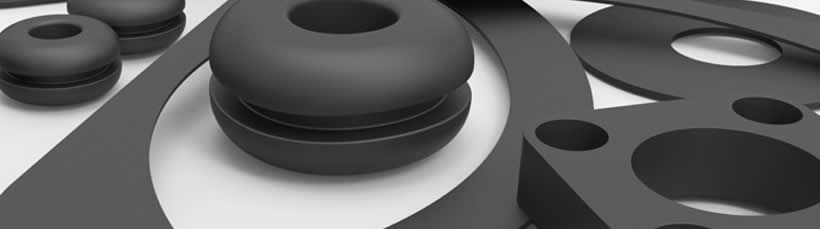

We manufacture prototype and bespoke gaskets in high quality silicone rubber. We can manufacture silicone gaskets in high and low volumes.

Silicone rubber SI is a rubber-like material composed of silicone with carbon hydrogen and oxygen.

In its uncured state, silicone rubber is a highly-adhesive gel or liquid. In order to convert to a solid, it must be cured, vulcanised or catalysed. This is normally carried out in a two-stage process at the point of manufacture into the desired shape, and then in a prolonged post-cure process.

Temperature Range;- -60 °C to +230 °C ( 250 °C intermittent) Burning Point 1000 °C

High Temperature grades -60 °C to +270 °C

Burning Characteristics; - Inconsistent burning with Mild sweet peroxide smell with white fumes.It is self-extinguishing immediately after removal of the flame and goes into a white ash.

Silicone rubber sheet may be cured by a peroxide cure system or a Platinum-catalysed cure system.

Peroxide cure system

Peroxide curing is widely used for curing silicone rubber sheeting. The curing process leaves behind by products, which can be an issue in food contact and medical applications. However, these products are usually treated in a post-cure oven which greatly reduces the peroxide breakdown product content.

Platinum cure system

In a platinum-based silicone cure system with platinum as catalyst there are no by-products, therefore it is suitable for medical products. Platinum cured sheet generally has higher physical properties also.

Silicone rubber has a relatively low tensile strength and poor tear and abrasion resistance; however it exhibits good heat and weathering resistance.

Silicone rubber is highly inert and does not react with most chemicals, and it is suitable for use in hot air, engine and transmission, animal and vegetable oils and greases, brake fluid and fire-resistant hydraulic fluids.

Silicone rubber is NOT recommended for use with Super-heated water/steam, acids and alkalis, aromatic mineral oils and hydrocarbons or hydrocarbon based fuels

There are many special grades and forms of silicone rubber, including: steam resistant, metal detectable, high tear strength, extreme high temperature, extreme low temperature, electrically conductive chemical/oil/acid/gas resistant, low smoke emitting, and flame-retardant. A variety of fillers can be used in silicone rubber, although most are non-reinforcing and lower the tensile strength. Silicone rubber is available in a range or hardness levels, 10 to 100 shore. It is also available in virtually any colour, and can be colour matched.

All grades Solid or Sponge can be supplied plain or with high temperature adhesive backing

We stock a wide range of Red; White; Black and Blue 60° Shore FDA 21 CFR 177-2600 and EC 1935:2004 Compliant Silicone; Approved for use with potable water up to 85ºC in accordance to BS 6920 Thickness range;- 0.8, 1, 1.5,2, 3, 4, 5, 6, 10, 12,15,20,25

Blue Metal Detectable Silicone; this has a detectable iron powder cut to 300 fine mesh in the ratio of 15 p.p.h. complete with a silicone rubber binder. This makes the rubber visible to metal detector scanning equipment; so that any rubber contamination in the product can be easily identified.

Translucent 40° shore; is a soft silicone solid FDA 21 CFR 177-2600 and EC 1935:2004 Compliant Silicone rubber. Approved for use with potable water up to 85ºC in accordance to BS 6920

Yellow or Blue Micra-Sil® Antimicrobial Silicone; Silicone Rubber offers microbial protection against bacteria, fungi and algae for the medical, pharmaceutical, food and beverage process industries. Silver is within the rubber and bacteria absorbs the free silver ions on the surface the bacteria is destroyed by breaking down their cell walls. The silver ions inhibit the growth of any micro-organisms and deter them from contaminating or colonising its surface. The free silver ions on the outside of the rubber remain active even after several washes This is Independently tested and has been found to destroy on contact – MRSA, E-coli, Salmonella, Campylobacter, etc.

Silicone Sponge is stocked in two densities, medium;256kg/m3 (16lb/ft3) and firm; 325kg/m3 (24lb/ft3) in a range of thicknesses with or without high temperature adhesive backing.