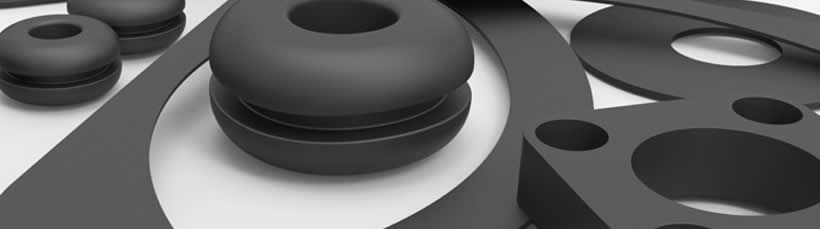

We manufacture prototype and bespoke gaskets in high quality Nitrile rubber. We can manufacture Nitrile gaskets in high and low volumes, to high tolerances.

Nitrile rubber, also known as Buna-N, Perbunan, Acrylonitrile Butadiene Rubber, and NBR, is a synthetic rubber copolymer of acrylonitrile (ACN) and butadiene.

Nitrile butadiene rubber (NBR) is a family of unsaturated copolymers of 2-propenenitrile and various butadiene monomers (1, 2-butadiene and 1, 3-butadiene). It is generally resistant to oil, fuel, and other chemicals (the more nitrile within the polymer, the higher the resistance to oils but the lower the flexibility of the material). Permeability for gasses can be poor depending on the compound.

NBR's temperature range −40 to 108 °C Ignition Temp 313C to 514C

Burning characteristics: - Continuous burning with minor crackling giving off an unpleasant acrylic smell with black fumes and soot. The residue is tacky.

Nitrile rubber is more resistant than natural rubber to oils animal and vegetable fats and dilute acids diesel fuel ozone and sour gas and has superior strength, but has inferior flexibility.

Nitrile rubber is generally resistant to aliphatic hydrocarbons;-. Methane, Ethane,

Propane, Butane, Pentane, Hexane, Octane.

Nitrile, like natural rubber, can be attacked by ozone, ketones, esters aldehydes chlorinated and nitro hydrocarbons (trichloroethylene) glycol- based brake fluids and Organic acids.

High quality Nitrile specification rubber sheet for the Aerospace and Defence industries is made to BS2751; 2001 We hold stocks of grades BA40 BA50 BA60 BA70 BA80 and BA90 from 0.5mm to 10mm.

White Food Safe Grade Nitrile Rubber (NBR) Sheeting conforms to EU1935:2004 2023/26 & FDA CFR 177 Sub Part C 177.2600 It is available in 60 shore hardness. Food safe Nitrile is also available in blue 65 shore.

Nitrile Rubber Matting is available in many patterns, Fine and Flat Fluted, Penny and Checker plate.

Hydrogenated Nitrile Rubber.

Depending on filler selection and loading, HNBR also known as High Saturated Nitrile Rubber compounds typically have tensile strengths of 20–31 MPa when measured at 23 °C.

Compounding techniques allow for HNBR to be used over a broad temperature range, -40 °C to 165 °C, with minimal degradation over long periods of time. For low-temperature performance, low ACN grades should be used; high-temperature performance can be obtained by using highly saturated HNBR grades with white fillers. As a group, HNBR elastomers have excellent resistance to common automotive fluids (e.g., engine oil, coolant, fuel, etc.) and many industrial chemicals. Like NBR, fluid and chemical resistance improves as the ACN content is increased.