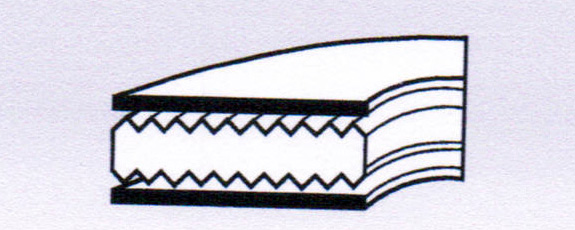

Camprofile gaskets consist of a metal core with concentric serrated grooves on each side and the addition of a soft layer of sealing material bonded to each face.

Selection of the metallic core material and sealing layer materials is dependent on the service duty.

The serrated metallic core is very effective for sealing in applications where high temperatures, high pressures and fluctuation conditions exist and can in fact be used without sealing layers, but by doing so there is a risk of flange damage, especially under high seating loads. The sealing layers protect the flange surfaces from damage and also offer excellent sealing properties when supported by the serrated metal core.

The advantages of using a Camprofile gasket, is that it can seal pressures up to 25MPa/250bar. Higher pressures 1500/2000psi can be considered by our technical department. Dependent on core and facing layer materials it can withstand temperatures up to 1000C, it can maintain effective sealing performance in varying temperature and pressure conditions. The serrated core can be reused subject to inspection and cleaning and re facing.

Core materials can be Stainless steel 304 316 320 347 310, Monel 400 and K500 Nickel 200, Inconel 600 625 X750 Hastelloy HB2 C276 Copper and Duplex.

Facings can be Graphite (up 500C) PTFE (up to 260C) or Mica and soft metals as Aluminium and Silver.

Depending on the manufacturer the Camprofile name can be spelt differently, such as Kammprofile® Metakamm® Maxiprofile®.